Find Wholesale Soft Toys Suppliers

Soft toys are more than just cuddly companions; they offer emotional comfort and a sense of security, making them essential items for kids and thoughtful gifts for all ages. When sourcing suppliers, prioritize quality materials and safety standards to ensure durability and compliance with regulations, while also considering unique designs and customization options that can set your offerings apart in a competitive market. Remember, successful partnerships with suppliers should emphasize reliability and responsiveness to ensure a smooth supply chain and meet customer demands effectively

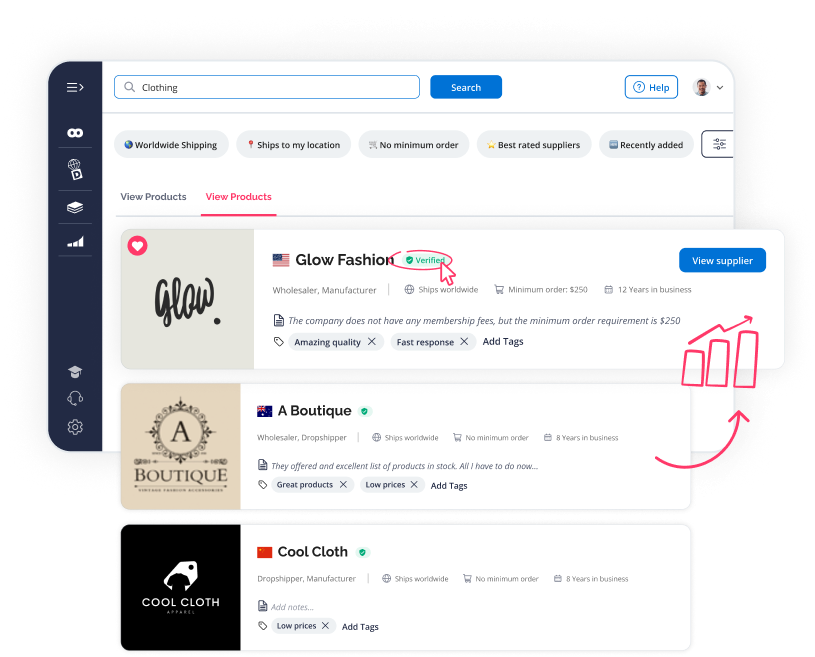

Here’s a selection of suppliers waiting for your call

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

24 Years in SaleHoo

24 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

4 Years in SaleHoo

4 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

6 Years in SaleHoo

6 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

20 Years in SaleHoo

20 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

9 Years in SaleHoo

9 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

23 Years in SaleHoo

23 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

1 Years in SaleHoo

1 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

10 Years in SaleHoo

10 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

25 Years in SaleHoo

25 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

15 Years in SaleHoo

15 Years in SaleHoo

Products stocked

About

Other product suppliers available...

Trusted by 137,000+ entrepreneurs worldwide

7-day trial today

suppliers in the USA and internationally.

Frequently Asked Questions

Soft toys must meet specific safety standards such as ASTM F963 in the U.S. and EN71 in Europe, which cover safety, material composition, and labeling. Ensure your suppliers provide certifications to confirm compliance.

Common materials include various grades of polyester, cotton, and plush fabrics, with stuffing often made from polyester fibers or natural materials like wool. Always inquire about the sourcing and quality of these materials to ensure safety and durability.

Most manufacturers are equipped to offer customization for designs, sizes, and colors, but minimum order quantities (MOQs) may apply. Discuss your design specifications early on to avoid delays in production.

Production lead times typically range from 4 to 12 weeks depending on factors like order size, complexity of design, and supplier capabilities. It's crucial to confirm lead times during negotiations to manage delivery expectations.

Implement a rigorous quality control process, including pre-production samples and in-line inspections during manufacturing. Consider partnering with third-party inspection services to ensure that the final products meet your quality standards before shipping.