Wholesale Tumblers for Online Sellers

Tumblers are an essential product for both everyday consumers and businesses, offering versatility in design and functionality that appeals to a wide range of preferences—from insulated travel mugs to stylish drinkware for events. When sourcing suppliers, consider the materials (such as stainless steel or durable plastic), customization options (like colors and sizes), and the supplier's ability to meet minimum order quantities and delivery timelines. Quality tumblers not only elevate your brand’s image but also encourage customer loyalty with their practicality in daily life

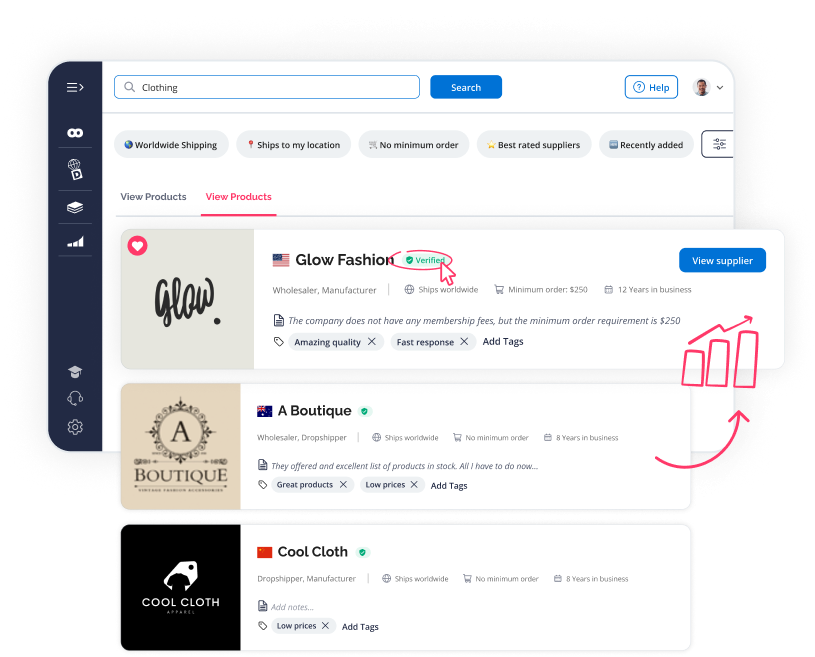

Here’s a selection of suppliers waiting for your call

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

15 Years in SaleHoo

15 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

9 Years in SaleHoo

9 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

$101 - $500

$101 - $500

23 Years in SaleHoo

23 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

18 Years in SaleHoo

18 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

28 Years in SaleHoo

28 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

7 Years in SaleHoo

7 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

27 Years in SaleHoo

27 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

9 Years in SaleHoo

9 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

21 Years in SaleHoo

21 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

6 Years in SaleHoo

6 Years in SaleHoo

Products stocked

About

Other product suppliers available...

Trusted by 137,000+ entrepreneurs worldwide

7-day trial today

suppliers in the USA and internationally.

Frequently Asked Questions

Common materials for tumblers include stainless steel, BPA-free plastic, and glass. Stainless steel tumblers are favored for their durability and insulation properties, while plastic options are lighter and often feature colorful designs.

Popular printing methods for customizing tumblers include screen printing, laser engraving, and heat transfer. Each method has its advantages, such as durability and design complexity, which should be considered based on the intended use.

MOQs can vary widely based on the supplier and customization options, ranging from 100 to 1,000 units. It's important to clarify MOQs upfront to ensure they align with your budget and inventory needs.

Lead times typically range from 2 to 8 weeks, depending on factors like order size, customization, and the supplier's location. Always confirm lead times with your supplier to manage expectations effectively.

Implementing quality control measures such as requesting samples, conducting factory visits, and reviewing third-party inspection reports can help ensure product quality. Establishing clear specifications and expectations with suppliers is also crucial.