Wholesale Stationery Suppliers for Ecommerce Sellers

When sourcing stationery products, you're tapping into a vibrant market filled with endless creativity and utility, from beautifully designed notebooks to eco-friendly pens. High-quality stationery not only enhances productivity but also adds a touch of personalization to everyday tasks. When choosing suppliers, prioritize those who offer a blend of style, durability, and sustainable materials, and don't hesitate to request samples to ensure their products align with your brand's vision and values

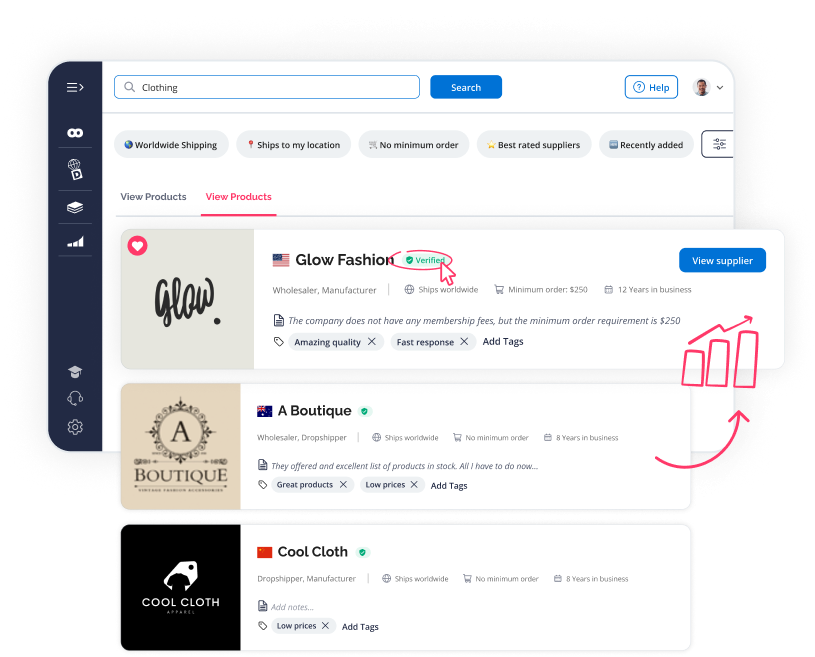

Here’s a selection of suppliers waiting for your call

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

15 Years in SaleHoo

15 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

24 Years in SaleHoo

24 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

22 Years in SaleHoo

22 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

1 Years in SaleHoo

1 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

8 Years in SaleHoo

8 Years in SaleHoo

Products stocked

About

Manufacturer Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

1 Years in SaleHoo

1 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

21 Years in SaleHoo

21 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

18 Years in SaleHoo

18 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

22 Years in SaleHoo

22 Years in SaleHoo

Products stocked

About

Wholesale Supplier

Verified

Verified

Join to contact this supplier

Join to contact this supplier

No Minimum Order

No Minimum Order

1 Years in SaleHoo

1 Years in SaleHoo

Products stocked

About

Other product suppliers available...

Trusted by 137,000+ entrepreneurs worldwide

7-day trial today

suppliers in the USA and internationally.

Frequently Asked Questions

Common materials for stationery include wood pulp for paper, plastics for binders, and metal for clips. The quality of these materials can impact the durability, printability, and overall aesthetic of the final product.

Minimum order quantities can vary widely among suppliers, typically ranging from 100 to 1,000 units. It's important to discuss MOQs upfront to ensure they align with your business needs and budget.

Inquire about certifications such as FSC (Forest Stewardship Council) for paper products and request documentation or reports that demonstrate eco-friendly practices. Suppliers committed to sustainability will readily provide this information.

Lead times can range from 2-4 weeks for production, depending on the complexity of the design and the supplier's capacity. Shipping time will also need to be factored in, which can vary based on the method and destination.

Implementing a robust quality control procedure is vital, which may include pre-production samples, in-process inspections, and final product audits. It's also beneficial to establish clear quality standards and communicate these with your supplier.